Explosion Suppression & Venting

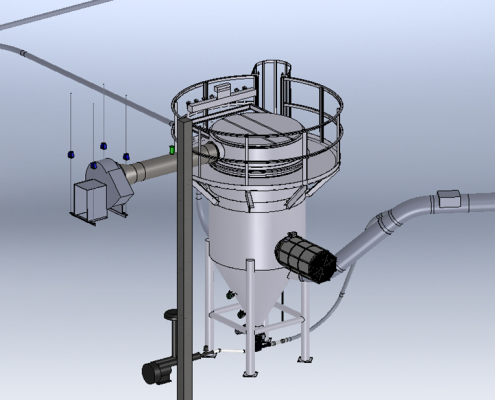

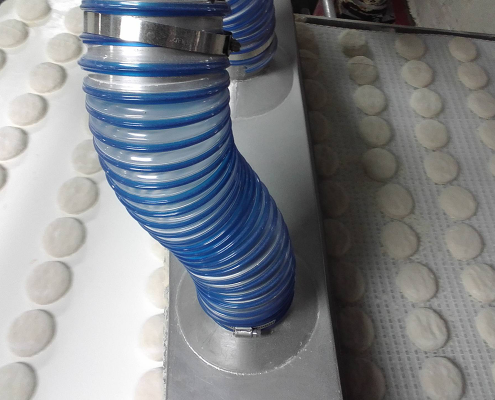

CSI purchases and designs explosion suppression systems and components that minimize the risk of a deflagration and reduce dust accumulations. Nonetheless the client is ultimately responsible for operational safety and code compliance. A variety of combustion detection and extinguishing devices are available to safely collect dust. Typically a baghouse will have a “Quench tube” to allow pressure to safely vent should static electricity or another ignition source initiate combustion. Equally important is a valve in the collection ducting that slams shut to prevent a secondary explosion.

Other solutions include chemical suppression in the baghouse and/or duct, and external venting. Some solutions will require periodic inspections at significant expense. Regardless, it is imperative that the baker maintain documentation as to the system requirements, maintenance, and operator training. In addition to the suppression and safety apparatus, CSI will ensure that the dust collection ducting design will maintain sufficient velocity to prevent the accumulation of dust inside, and balance dust collection from the designated locations.