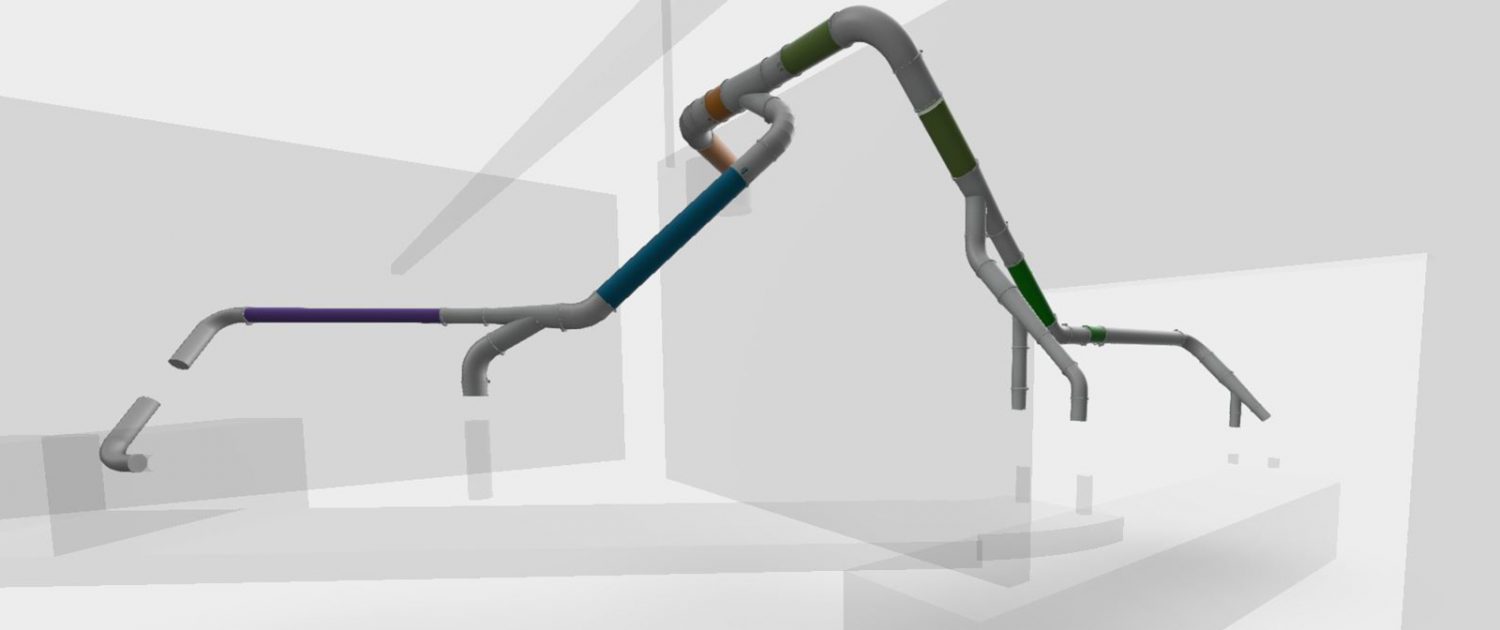

Bakery Ingredient Dust Collection

Campbell Systems has years of experience specializing in BAKERY DUST COLLECTION SYSTEMS for many applications within wholesale bakery and dough makeup operations, improving the environment and product quality!

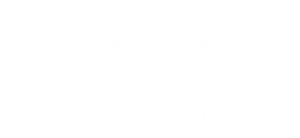

Flour Dust Reclaim Systems

Flour is expensive! Reclaim systems reduce waste and sanitation time, but not all are created equal. SAVE MORE FLOUR MAKE MORE DOUGH with Campbell Systems!