Bakery Dust Collection & Flour Reclaim Systems

With tight margins and ever increasing regulatory challenges, wholesale bakeries seeking to capture Flour and Cornmeal Dust can rely on CSI! Ingredient dust collection provides tangible paybacks in sanitation time and maintenance savings and substantial ingredient cost savings when the dust can be reused. In addition, wheat flour is classified as combustible dust by OSHA. Capturing rogue dust yields health and safety benefits while offering a solid Return on Investment!

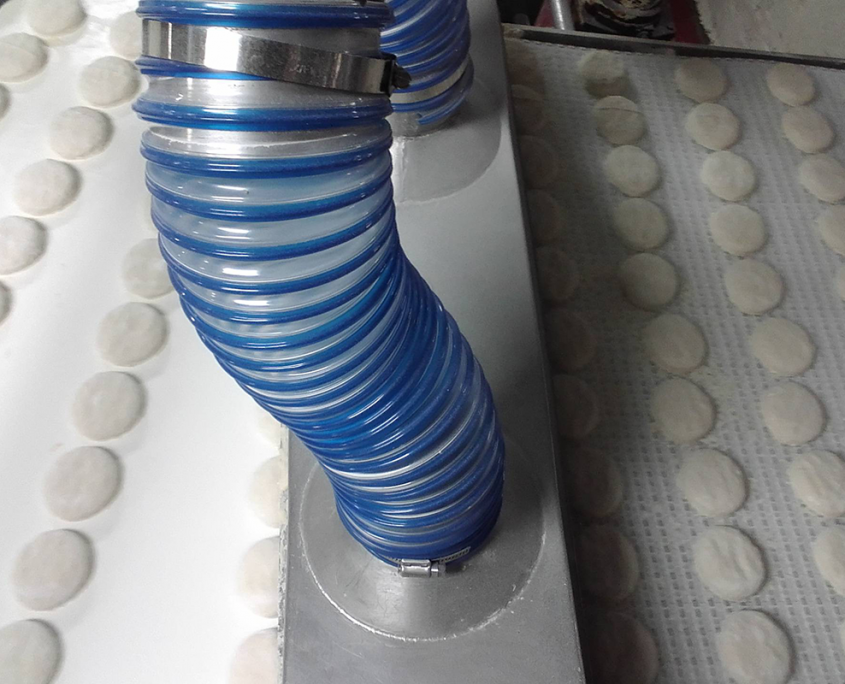

To realize these benefits economically and reliably in a food production environment, especially for flour dust, specialized dust collection equipment is a must. It must be efficient, sanitary, and easy to clean and maintain with food grade product and air filtration – most dust collectors don’t and will prove more expensive to operate and potentially expose your bakery to costly product recalls!

CSI offers economical proven solutions for bread, roll, bagel and muffin lines, including complete systems, safety and performance upgrades for existing dust collectors, related aftermarket items such as filters, flour sifters, proofer cups, belting, and peel board cleaning equipment.

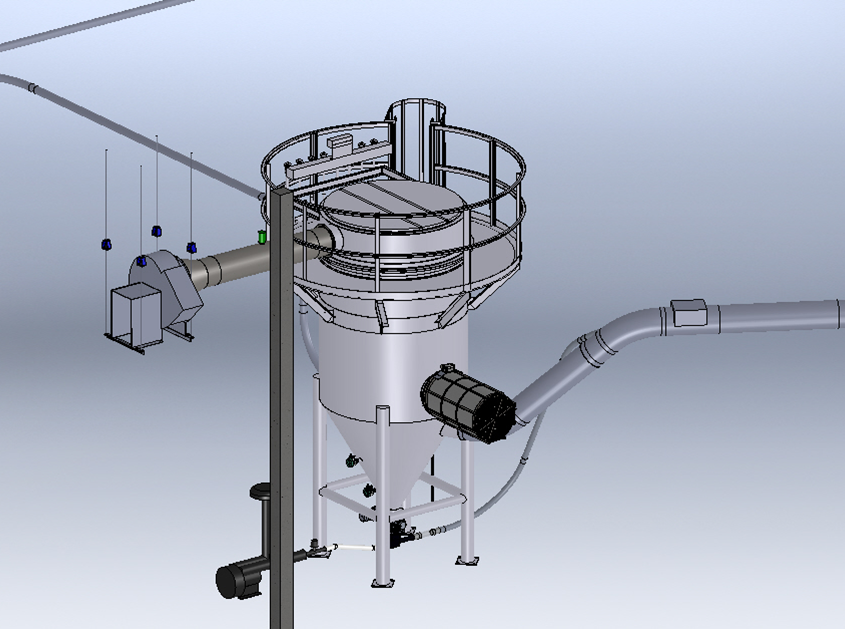

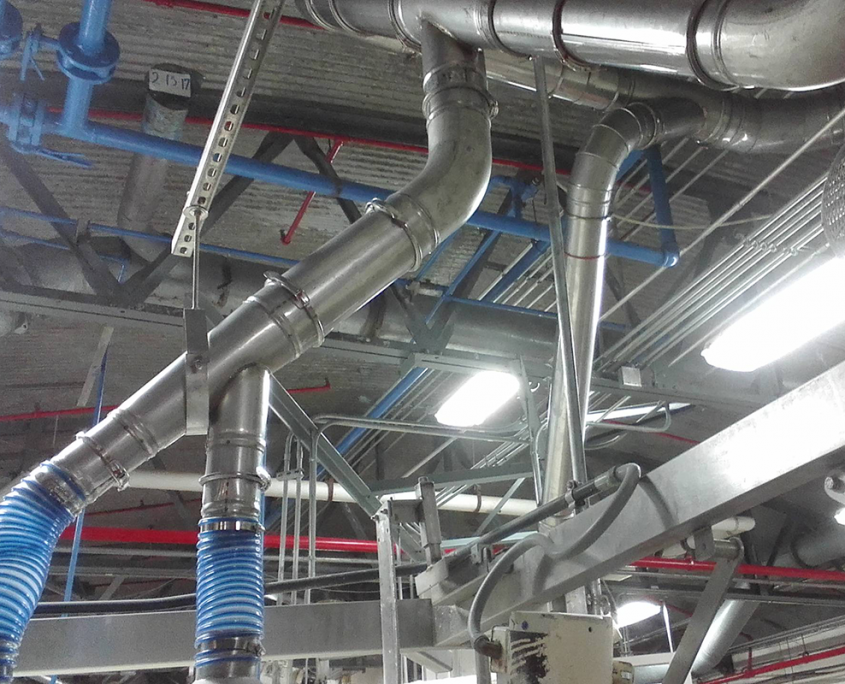

Proper performance and trouble free installation are not an accident at CSI. Expect complete satisfaction thanks to our baking industry experience combined with application input from your engineering, production, and sanitation teams, and a philosophy of engineered solutions instead of “one size fits all” hardware. CSI is able to provide superior, cost effective results thanks to 3D design software, lean manufacturing, and quality vendors for commercially available components such as airlocks, blowers, cyclones, and combustible dust safety equipment. When appropriate we can even integrate existing equipment and source from your preferred component vendors!

With many years of serving the industry leaders.

CSI has provided systems for all types of production methods…

Our Workflow…

Step 1: Production needs are the most critical component to designing a system that meets your needs. Every product and production requirements are unique and your flour & dust reclaim solution should be as well.

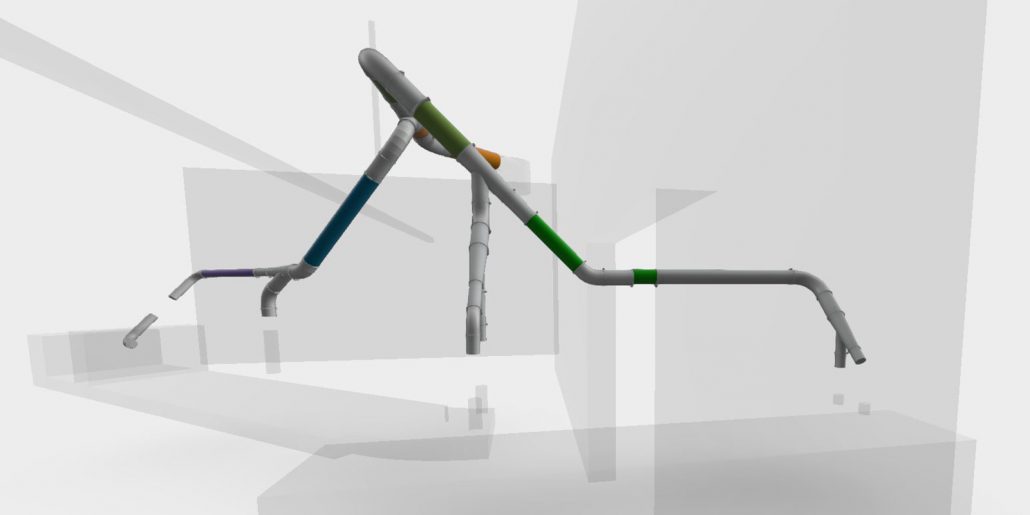

Step 2: Determine available space allowances within the production room including ceiling height, walls, overhead obstructions. It’s critical that we record all variables to properly design a system that fits without conflicting with others systems or building mechanical systems.

Step 3: Design a system in 3D that meets your production needs and fits within the available space for a smooth installation and operation.

What you need to provide…

To engineer a dust collection or flour reclaim system, CSI will need to completely understand your production details. Starting with what product you produce, the daily volume, or hourly rate for each we will begin to evaluate your needs. We will need to understand the flour dusting requirements for each product.

The best way to get started would be to provide us with pictures of the production line, a line layout preferably in a CAD format, and a product data chart showing rates, volume, product patterns etc… This basic information will give us a good starting point to build upon when we conduct a site inspection of your production.