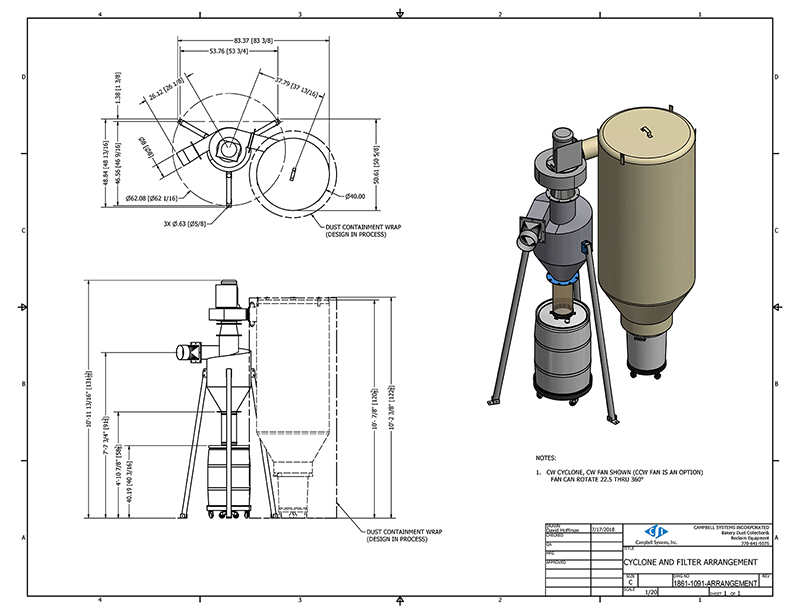

Cyclone & Filter Arrangements

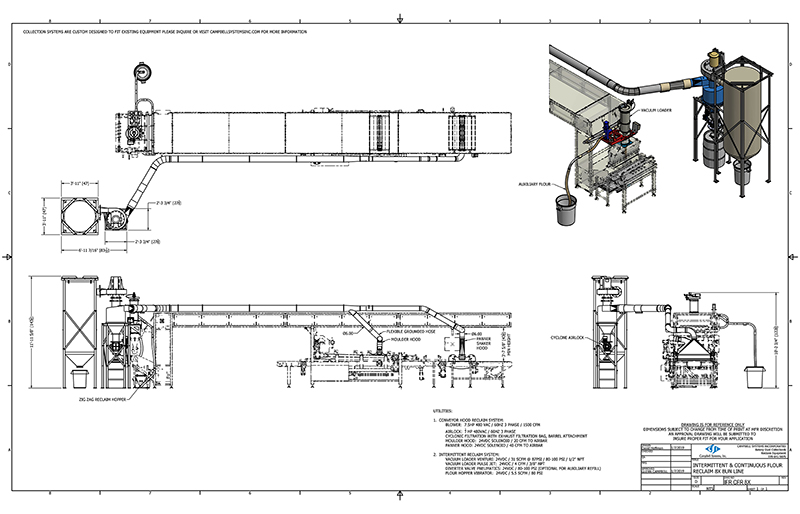

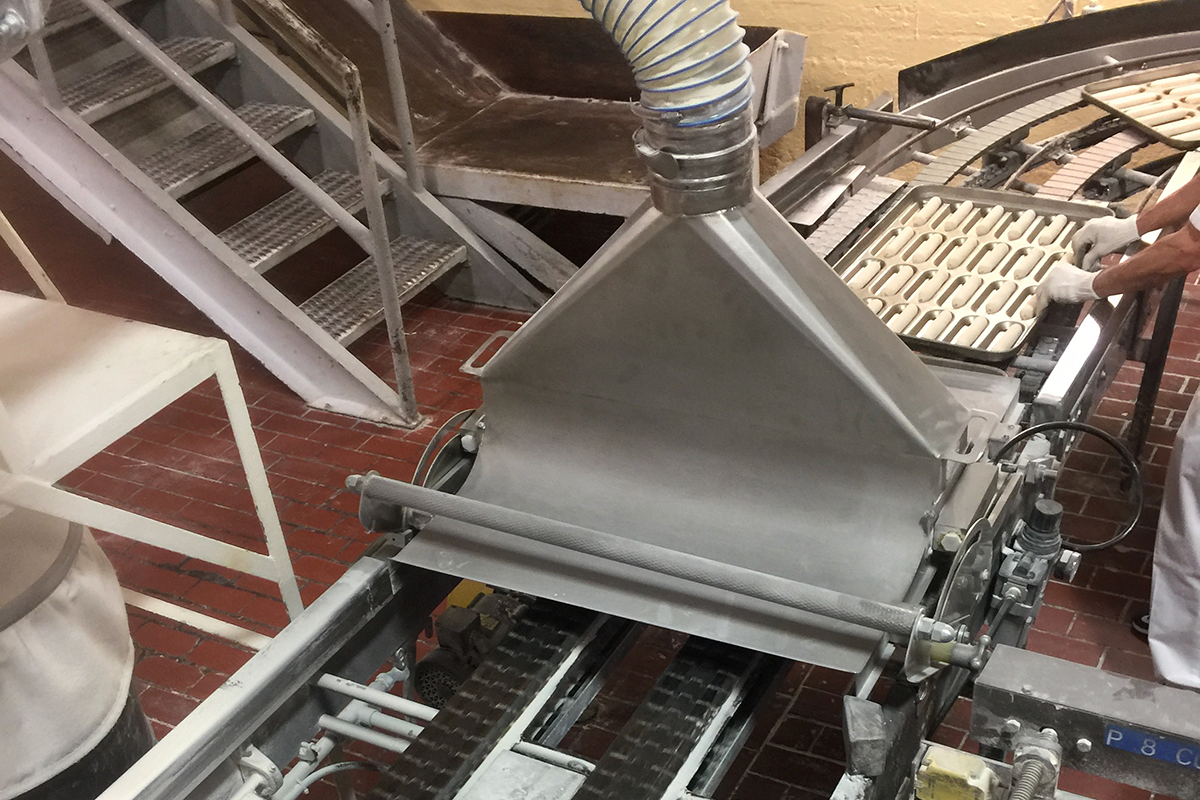

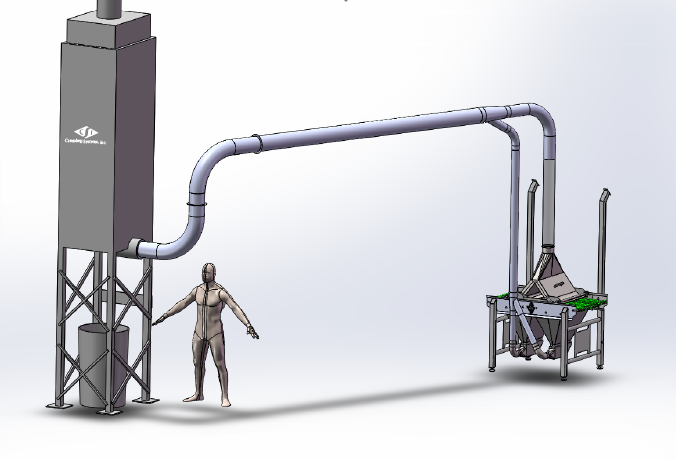

EZ Flow Dust Reclaim System

Our EZ Flow Intermittent & Continuous Flour Reclaim System for 8 pocket Bun Lines are designed for peak efficiency. Equipped with multiple collection hoods along the moulding and pan shaking operations excess flour is removed prior to pans discharging for proofer loading. Our system also includes auxillary flour reclaim at the zig zag boards prior to intermediate proofing including optional automated vaccum flour hopper loading.

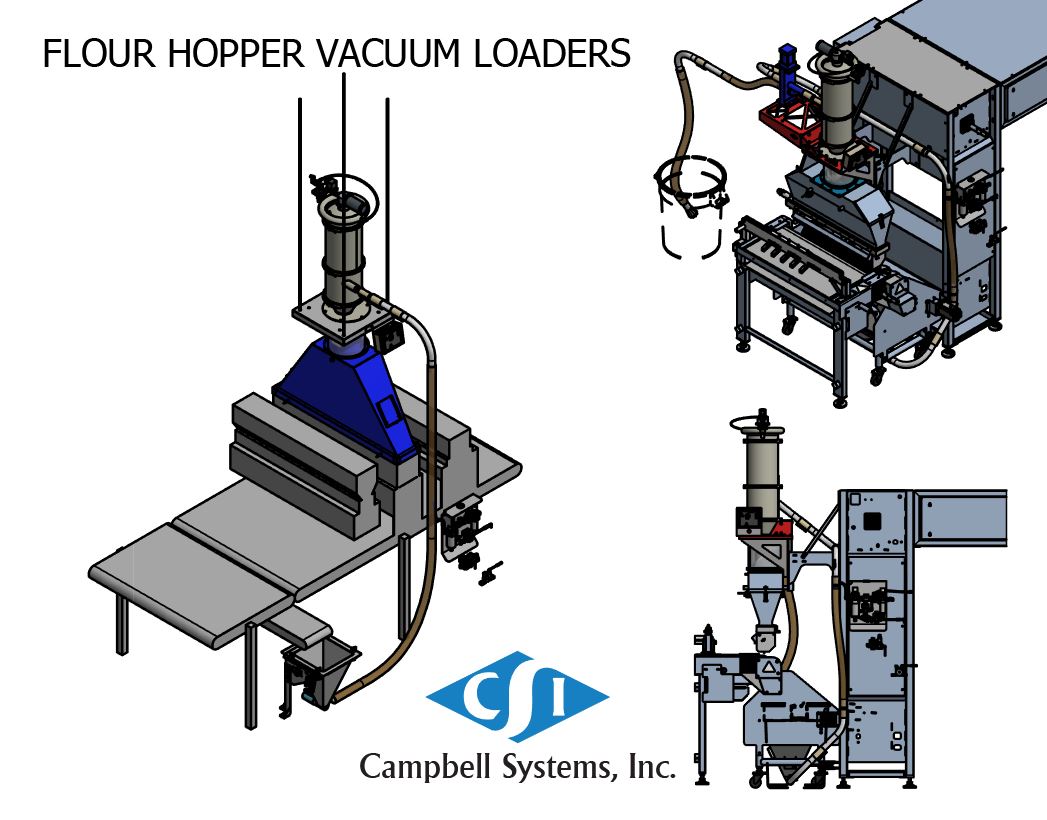

Our Flour Hopper and Sifter Vacuum Loaders automatically redistribute reclaimed flour back into the production process. After flour is reclaimed we sift and redeposit the flour back to the point of distribution from a sifter above the moulding line. Our Vacuum Loaders can be supplied as a part of a new system or as a stand alone install on an existing line.

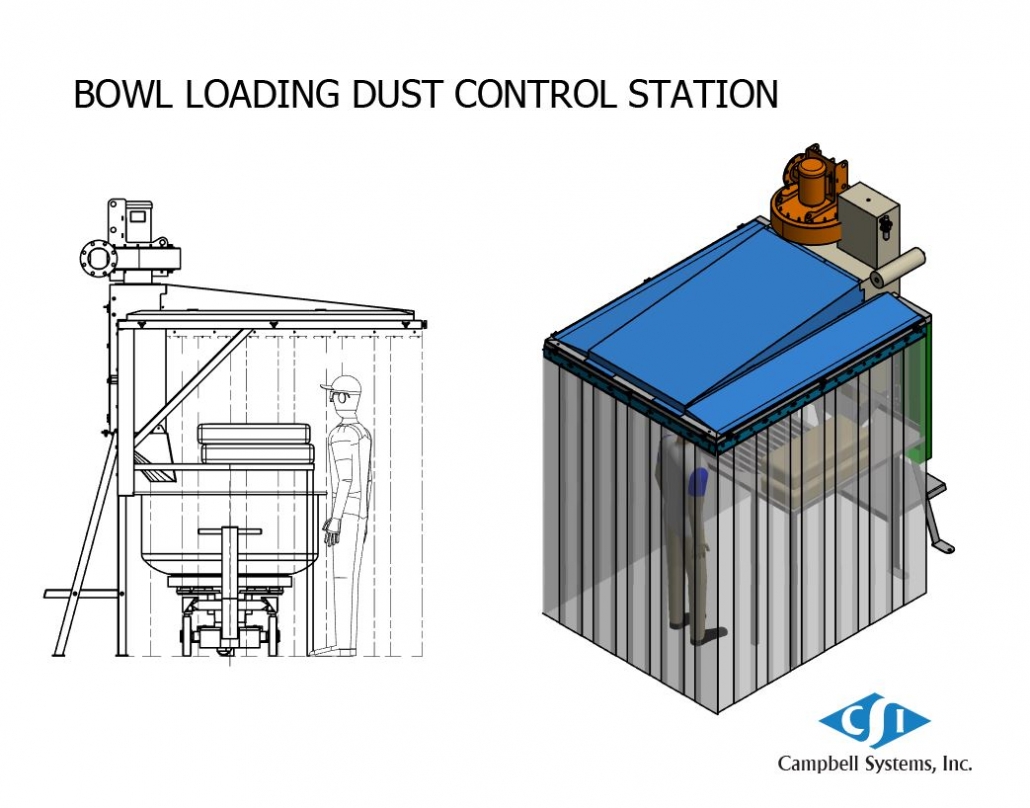

Bowl Loading Dust Control Station

CSI’s Bowl Loading Dust Control Station is design to support manual bag dump operations. Dust Control for Bag Dump Stations is greatly lacking in most installed systems. With our upgraded Bowl Loading Station equipped with a vacuum exhaust system and curtain wall for dust containment you can keep your bakery more free of dust by collecting at the bag dump process.

Pan & Peel Cleaning Systems

Peel Board Cleaner

Campbell Systems Peel Board Cleaner is used for Bagel and Hearth Bread systems using Plastic and Wooden Peels. Our system features a split leg vacuum hood above the peel as well as a dual vacuum nozzle below the peel to clean the bottoms. We design our systems based on your needs including the addition of brushes and rubber scrapers.

Peel Board Cleaner with Reclaim

Typically peel boards are pre-dusted with flour and/or cornmeal for product release and artisan characteristics. CSI powered brush “cleaners” feature an integral collection hood to limit the buildup of product and dust on the board, and more importantly, prevent surplus dust from being expelled into the production environment downstream of the TOL during conveying or stacking.

- Hinged, close fit hood prevents dispersion of dust, residual dough, etc.

- Floating, readily replaceable brush with low maintenance shaft mounted gear motor

- Conveyor with top and bottom brushes, or top only design to install on an existing conveyor

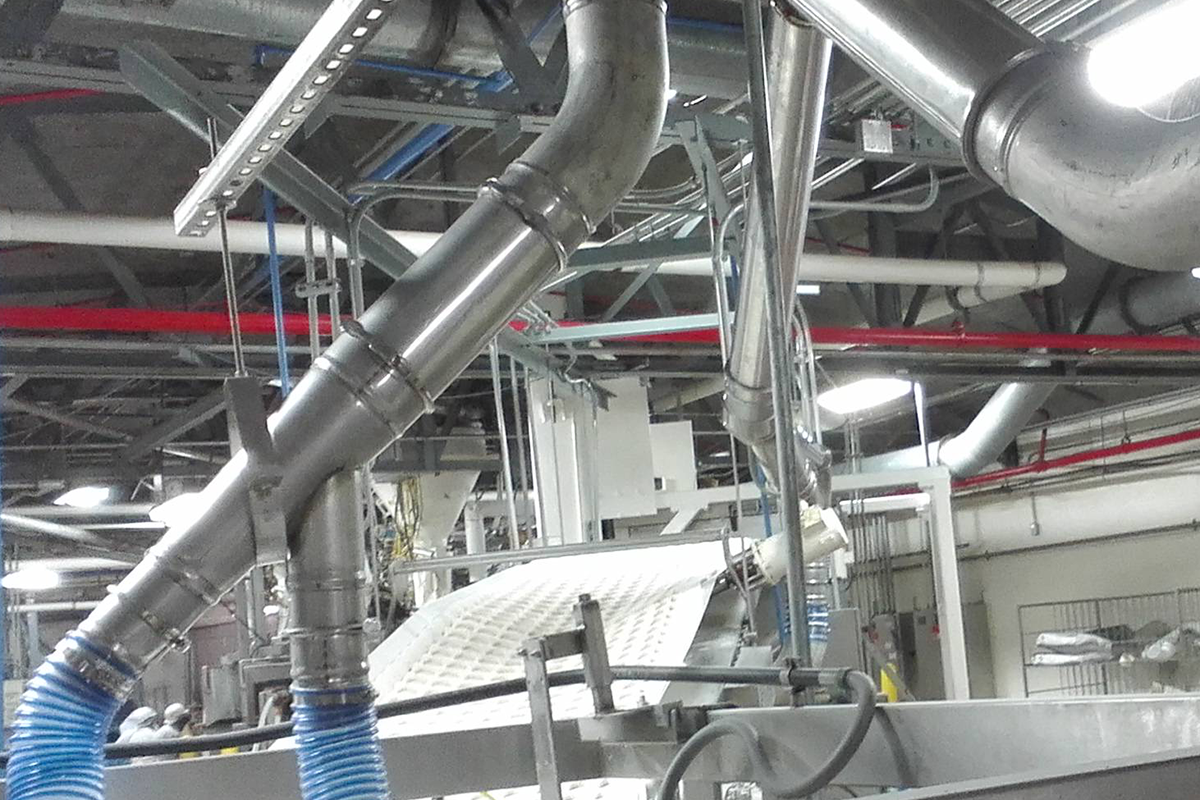

Pan Cleaner Vacuum Hood and Cyclone

Our Pan Cleaning Vacuum nozzle and cyclone is a small customizable system that is built to suit your conveyor height and elevation. Our system is easy to install over your existing conveyors and typically requires no conveyor modifications. Our cantilevered collection hood provides a high CFM extraction of debris within a pan for the collection of loose debris in the pans. Our hoods are also equipped with a compressed air nozzle to loosen debris for extraction. All debris is transferred to a nearby collection barrell under the cyclone.

Learn More about Campbell Systems

Campbell Systems provides a wide range of Dust Collection Systems and designs custom solutions to meet your needs. We also provide specialized cleaning solutions including Pan and Peel Cleaning. To Learn more download our brochure or contact us to discuss in more detail.