Component Replacements & System Upgrades

Attention to detail is invaluable whether considering system upgrades or new production lines to gain substantial savings. Key features and available CSI aftermarket components include the following:

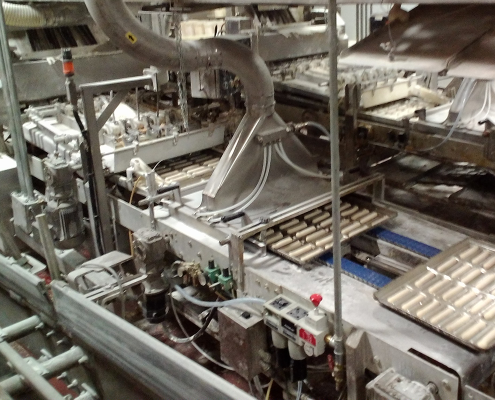

- Collection hoods must “fit” the locations, be sanitary, sturdy, and have the proper configuration to capture the dust with the minimum possible CFM!

- Air bars are required to fluidize dust in pan molds and on top of product. For food safety we typically provide a .01 micron coalescing air filter along with solenoid and pressure regulator.

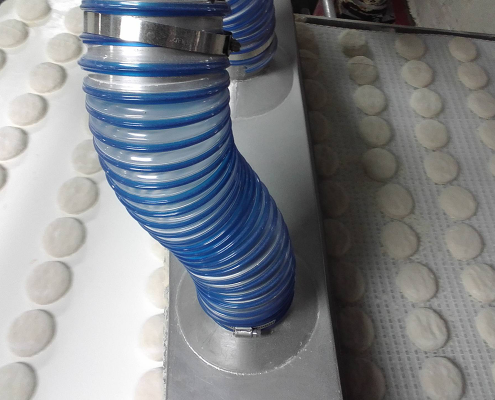

- Replacing “T’s” and lengthy flex hose with rigid duct, sweep elbows and expanding laterals will improve airflow and help achieve the mandated air velocity in each leg. Flexible hoses (other than short lengths necessary at the hood connection) waste energy, cannot be cleaned, and are not code compliant. Lastly, CSI duct will be properly bonded, grounded, and resistance verified at installation.

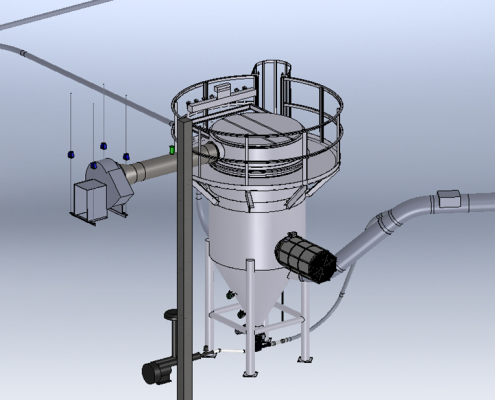

- Adding a cyclone to “pre-filter” the dirty air prior to the baghouse will greatly improve its performance and maintenance requirements.

- “Bag houses” larger than 8 cubic feet must be replaced or retrofitted with combustible dust protective equipment. For low maintenance and long filter life with less compressed air we utilize vertically mounted bag or cartridge filters with a conservative air/cloth ratio (< 5:1).